Roadside Safety Products

Industry leading crash test performance and money-saving benefits begin with the unique design features of Zoneguard® Temporary Steel Barriers, Smart Cushion® Impact Crash Attenuators, and ZoneBloc® Temporary Concrete Barriers. These signature creations offer the road construction industry and roadway workers a revolutionary product that provides superior protection.

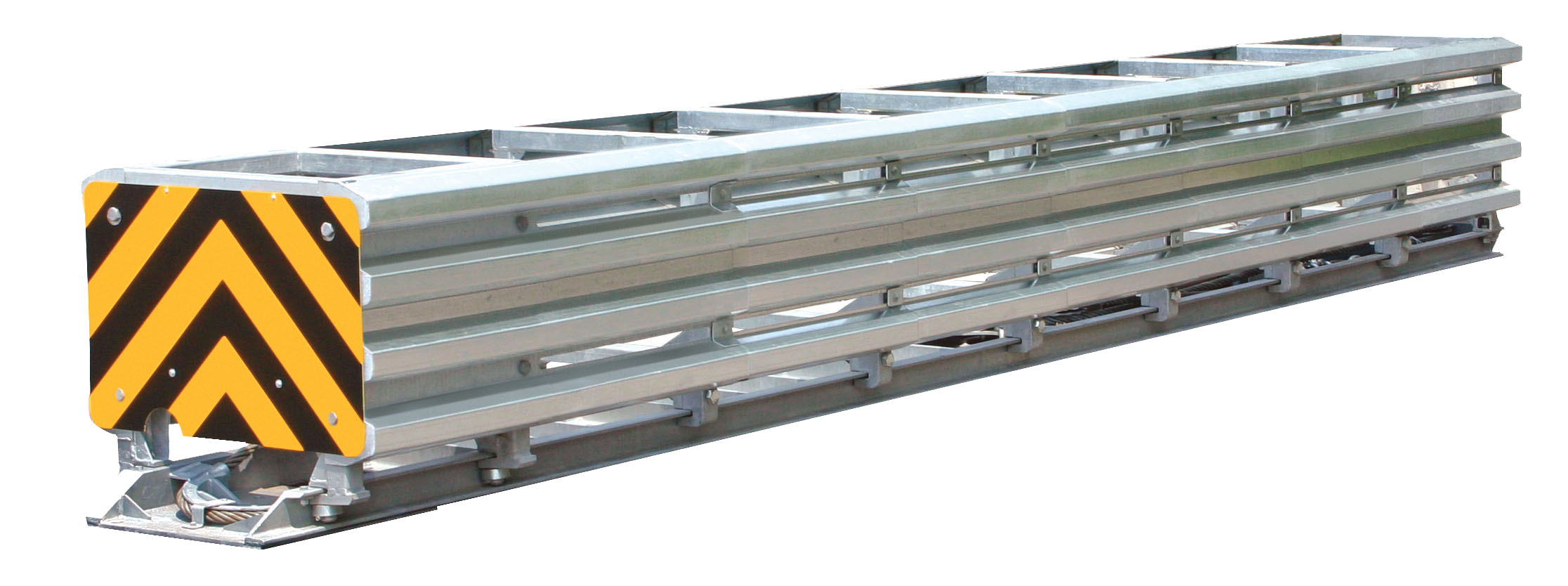

The World’s Only Speed-Dependent Crash Attenuators

The Smart Cushion® crash attenuator is a revolutionary, speed-dependent product that varies stopping resistance during an impact. The Smart Cushion® crash attenuator allows lighter and slower-moving vehicles to have longer ridedown distances and lower ridedown g-forces.

Unlike fixed-resistance attenuators, the Smart Cushion® attenuator does not reach maximum stopping resistance unless a vehicle is traveling at the maximum design speed. This fully re-directive, non-gating, bidirectional, impact attenuator was designed for maximum safety and reusability, as well as outstanding durability before, during and after an impact.

The Smart Cushion® is the only attenuator with a reverse-tapered design to eliminate side panel stress during a collapse. Plus, it is the only fully redirective attenuator tested to MASH and NCHRP 350 with no changes!

Features

Specs

SCI70GM / TL2

SCI100GM / TL3

How It Works

The hydraulic porting of the attenuator ensures that the proper resistance is used to stop the vehicle before it reaches the end of the cushion’s usable length. The Smart Cushion® was specifically designed for durability and resetability to enable resets to be performed in less than 30 minutes.

A unique attribute of the Smart Cushion® is that side impacts on the road rarely require any repairs. This eliminates mobilization, repair labor, and parts after side impacts which average of 30% – 40% of the incidents depending on the roadway geometrics.

After an impact, the cushion requires a dual-stage pull-out with the replacement of two 1/4″ shear bolts. The crash attenuator requires a minimal inventory of spare parts because of the new side panels’ durability and the normal requirement of only two shear bolts on the frontal impact reset. Minimal damage means quick resetting and reduced worker exposure to traffic, as well as lower costs for traffic control, replacement parts and labor.

MASH Test Results

- All MASH tests were performed including the optional midsize car test using an independent accredited testing facility.

- The Smart Cushion is a MASH and NCHRP 350 tested attenuator.

SAFETY BENEFITS

- Quick and easy resets for reduced worker exposure to traffic.

- Variable resistance provides consistent deceleration during ridedown.

- Longer ridedown distances and lower sustained g-forces for lighter or slower-moving vehicles.

- Low angle of exit on side impacts.

- Side impact performance reduces public and worker exposure

Cost Benefits

- Few replacement parts requirement virtually eliminates spare parts inventory and parts costs.

- Thirty minute resets reduces labor and traffic control costs.

- The reverse-tapered design eliminates side panel stress on frontal impacts to reduce damage and system fatigue from multiple impacts.

- Life cycle cost savings increase dramatically as additional impacts occur.

- No damage on side impact combined with low cost on frontal impacts can save you 75% or more on costs including labor, mobilization, and parts

- Systems shipped from factory fully assembled reduce on-site labor.

Technical Documents

Have technical questions? Below are some documents that should help, but don’t hesitate to reach out to us if you don’t find what you’re looking for.